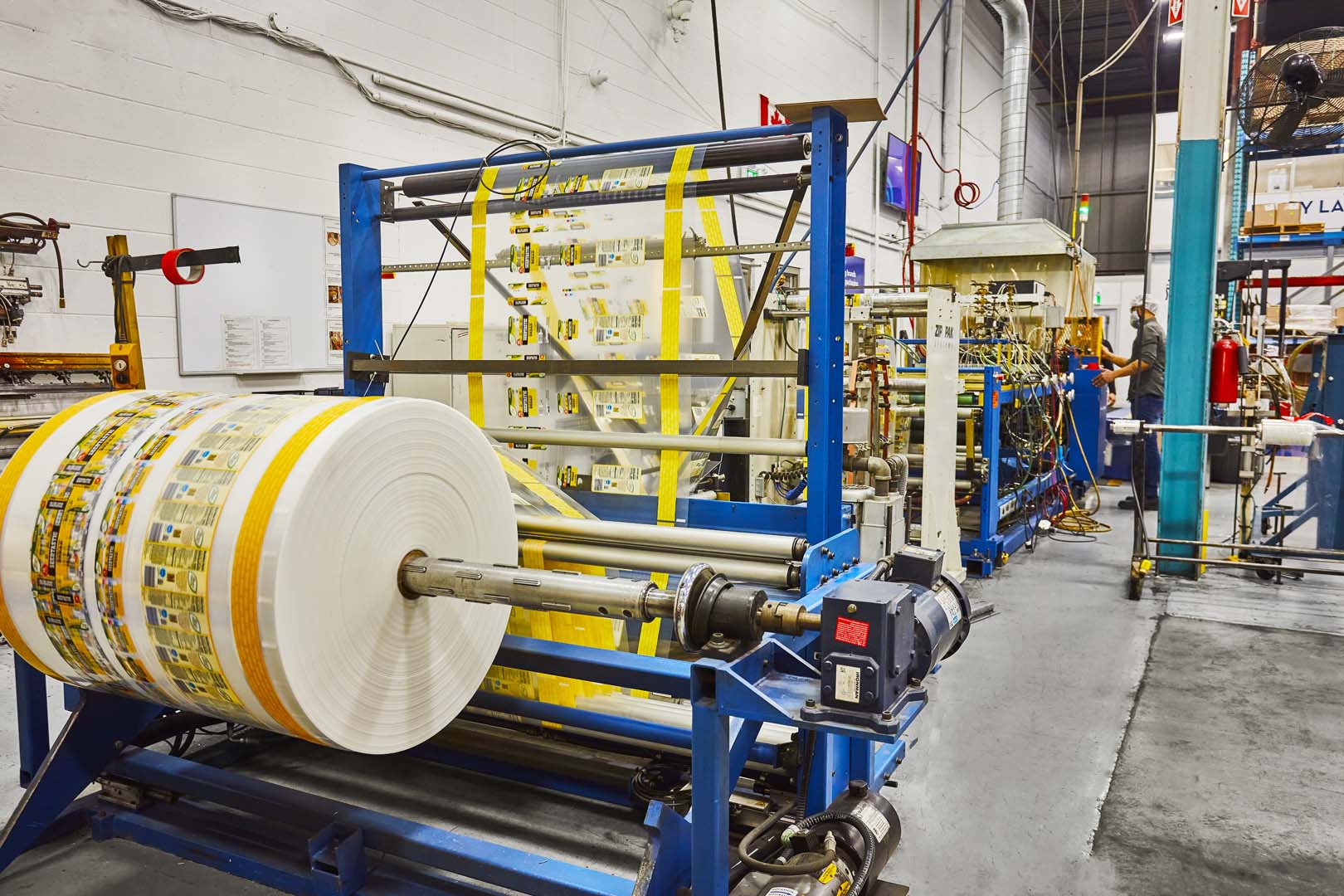

AlphaPoly’s bag converting provides packaging solutions for wicket bags, side seal bags, bottom seal bags and more to keep product fresh and secure.

![]()

Wicket Bags, Side or Bottom Seal Bags, & More

AlphaPoly’s packaging experts and machinery like the bag converter, will give you confidence that your poly bag will be created with care and precision. We’ve got your project in the bag, literally.

- Leak proof seals (both water and air tight)

- Multilane capabilities

- High speed wicket mounting

- Variety of venting options for any requirement

- Closures including: zippers, tapes, other reclosables

- Side gusset, bottom gusset, 3rd layer pockets

- Foldovers, sealed headers, reinforced handles

Things to Consider when Bagging Products

- Environmental impact

- Food grade materials

- Desired shelf life

- Matching label weight with actual weight

- How package will be displayed

- Package ergonomics

- Product safety

FAQs

Here’s some commonly asked questions about bagging.

Bag converting is a process where materials are transformed into finished bags. This involves cutting, folding and sealing the materials to create the desired bag shape and size. Alphapoly uses specialized bag converting machines to automate this process for efficiency and accuracy.

Bag converting can produce a wide range of bags. The process allows for customization in terms of size, shape, and design to meet specific needs and preferences. While the width and height aren’t limitless, we can surely help most brands get the right fit.

Yes, custom designs and logos can be easily incorporated into the bags produced through bag converting. Bag converting allows for flexibility in design, making it possible to create unique and branded bags that meet the specific needs and preferences of businesses and individuals.